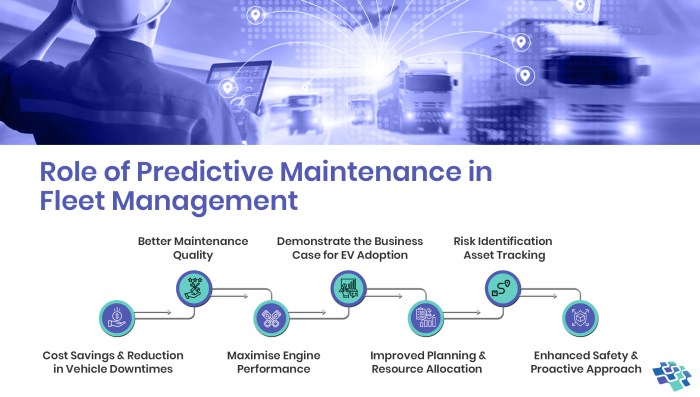

Delve into the realm of predictive maintenance in fleet operations, where cutting-edge technologies and innovative strategies converge to revolutionize the way maintenance is approached. This guide offers a glimpse into the future of fleet management, highlighting key trends and advancements that are shaping the industry.

As we navigate through the intricacies of predictive maintenance, it becomes evident that proactive measures can mitigate risks and optimize operational efficiency in ways previously unimaginable.

Importance of Predictive Maintenance

Predictive maintenance plays a crucial role in fleet operations by allowing companies to anticipate and address potential issues before they result in costly breakdowns. By utilizing data and analytics, fleet managers can schedule maintenance tasks proactively based on the actual condition of the vehicles, rather than relying on fixed schedules or waiting for signs of failure to appear.

Prevention of Costly Breakdowns

Predictive maintenance can help prevent costly breakdowns by identifying and addressing issues early on. For example, by monitoring engine performance metrics and detecting anomalies, fleet managers can schedule maintenance to replace worn-out parts before they cause a breakdown on the road.

This proactive approach not only reduces downtime and repair costs but also improves the safety of the drivers and the vehicles.

Impact on Overall Fleet Efficiency

Implementing predictive maintenance strategies can have a significant impact on the overall efficiency of a fleet. By ensuring that vehicles are well-maintained and in optimal condition, companies can minimize unplanned downtime and maximize the utilization of their assets. This leads to improved productivity, reduced operational costs, and enhanced customer satisfaction through reliable and timely service delivery.

Technologies Driving Predictive Maintenance

Predictive maintenance in fleet operations is increasingly relying on advanced technologies to optimize maintenance schedules, reduce downtime, and improve overall efficiency. Key technologies driving predictive maintenance include Internet of Things (IoT), Artificial Intelligence (AI), and machine learning.

IoT in Predictive Maintenance

IoT plays a crucial role in predictive maintenance by enabling real-time monitoring of vehicle components and systems. Sensors installed in fleet vehicles collect data on various parameters such as engine performance, fuel consumption, tire pressure, and temperature. This data is transmitted to a central database where it is analyzed to identify patterns and anomalies that indicate potential maintenance issues.

By leveraging IoT technology, fleet managers can proactively address maintenance needs before they escalate into costly breakdowns.

AI in Predictive Maintenance

Artificial Intelligence algorithms are used to process the vast amount of data collected through IoT sensors and other sources. AI systems can detect patterns, correlations, and trends that may not be apparent to human operators, leading to more accurate predictions of when maintenance is required.

By employing AI in predictive maintenance, fleet operators can optimize their maintenance schedules, reduce unnecessary servicing, and extend the lifespan of their vehicles.

Machine Learning in Predictive Maintenance

Machine learning algorithms enhance the predictive capabilities of maintenance systems by continuously learning from new data and refining their predictions over time. By analyzing historical maintenance records and sensor data, machine learning models can forecast when specific components are likely to fail and recommend preventive actions.

This proactive approach helps fleet operators minimize unplanned downtime, reduce maintenance costs, and improve overall fleet performance.

Implementation Challenges and Solutions

Implementing predictive maintenance in fleet operations can present various challenges that organizations need to address to ensure successful integration. These challenges can range from technical issues to organizational barriers. However, with the right strategies and solutions in place, these challenges can be overcome to maximize the benefits of predictive maintenance.

Common Challenges Faced

- Lack of Data Quality: One of the primary challenges is the availability and quality of data needed for predictive maintenance. Inaccurate or incomplete data can lead to incorrect predictions and unreliable maintenance schedules.

- Integration Issues: Integrating predictive maintenance systems with existing fleet management systems can be complex. Compatibility issues, data silos, and resistance to change can hinder the seamless integration of predictive maintenance solutions.

- Cost Constraints: Implementing predictive maintenance technology can require significant investment in infrastructure, training, and resources. Budget constraints can be a major hurdle for organizations looking to adopt predictive maintenance practices.

Strategies to Overcome Barriers

- Invest in Data Quality: Prioritize data quality by ensuring data accuracy, consistency, and relevance. Implement data validation processes and invest in data cleansing tools to improve the quality of data used for predictive maintenance.

- Collaborate Across Departments: Foster collaboration between IT, maintenance, and operations teams to facilitate the integration of predictive maintenance systems. Establish clear communication channels and roles to streamline the implementation process.

- Conduct Cost-Benefit Analysis: Perform a thorough cost-benefit analysis to showcase the potential return on investment of predictive maintenance. Highlight the long-term cost savings, reduced downtime, and improved fleet efficiency to justify the initial investment.

Role of Data Quality and Integration

Effective predictive maintenance heavily relies on data quality and seamless integration of systems. High-quality data ensures accurate predictions and proactive maintenance practices. Integration across various systems enables real-time data sharing, predictive analytics, and automated maintenance workflows. Organizations must prioritize data quality and integration efforts to unlock the full potential of predictive maintenance in fleet operations.

Cost-Benefit Analysis of Predictive Maintenance

Implementing predictive maintenance in fleet operations can have significant financial implications. By analyzing the costs and benefits, organizations can make informed decisions about their maintenance strategies.

Costs of Reactive Maintenance vs Predictive Maintenance

Reactive maintenance, which involves fixing equipment only after it fails, can lead to unexpected downtime, costly repairs, and disruptions to fleet operations. On the other hand, predictive maintenance uses data and analytics to identify potential issues before they occur, allowing for proactive maintenance and minimizing the risk of unplanned downtime.

Cost Savings with Predictive Maintenance

One of the key advantages of predictive maintenance is the potential for cost savings in the long run. By detecting and addressing maintenance issues early, organizations can avoid costly repairs, reduce downtime, and extend the lifespan of their fleet vehicles.

This proactive approach can result in significant savings on maintenance and repair expenses over time.

Future Trends in Predictive Maintenance

Predictive maintenance is constantly evolving, driven by advancements in technology and the increasing demand for more efficient fleet management solutions. Let's delve into some of the emerging trends that are shaping the future of predictive maintenance in fleet operations.

Emerging Technologies in Predictive Maintenance

- The Internet of Things (IoT) is revolutionizing predictive maintenance by enabling real-time monitoring of vehicle components and performance data. This allows fleet managers to predict and prevent potential breakdowns before they occur.

- Artificial Intelligence (AI) and machine learning algorithms are being used to analyze vast amounts of data collected from sensors and connected devices. This helps in identifying patterns and predicting maintenance needs with greater accuracy.

- Augmented Reality (AR) is being integrated into maintenance processes, providing technicians with interactive guides and real-time data overlays to streamline repair and maintenance tasks.

Impact of Autonomous Vehicles on Predictive Maintenance

- Autonomous vehicles are set to revolutionize fleet operations by reducing the need for human intervention and improving safety. Predictive maintenance plays a crucial role in ensuring the reliability and performance of autonomous vehicles.

- With the introduction of autonomous vehicles, predictive maintenance will become even more critical to prevent potential system failures that could lead to accidents or disruptions in operations.

- The integration of advanced sensors and self-diagnostic capabilities in autonomous vehicles will enable proactive maintenance measures based on real-time data analysis, optimizing fleet efficiency and minimizing downtime.

Future of Fleet Management with Predictive Maintenance

- Predictive maintenance will continue to play a central role in the future of fleet management, offering cost-effective solutions to optimize vehicle performance and extend asset lifespan.

- By leveraging predictive maintenance technologies, fleet managers can shift from reactive to proactive maintenance strategies, reducing maintenance costs and improving overall operational efficiency.

- The integration of predictive maintenance into fleet management systems will enable predictive analytics and prescriptive maintenance recommendations, empowering fleet operators to make data-driven decisions for enhanced fleet performance.

Closing Notes

In conclusion, the future of predictive maintenance in fleet operations holds immense promise for streamlining processes, reducing costs, and enhancing overall productivity. By embracing technological innovations and overcoming implementation challenges, fleet managers can pave the way for a more efficient and sustainable future.

FAQ Explained

What are some common challenges faced in implementing predictive maintenance?

Common challenges include data quality issues, lack of integration between systems, and resistance to change among stakeholders.

How can predictive maintenance lead to cost savings in the long run?

By identifying maintenance needs before breakdowns occur, predictive maintenance helps prevent costly repairs and downtime, ultimately saving on operational expenses.

What emerging technologies are shaping the future of predictive maintenance?

Emerging technologies such as blockchain, predictive analytics, and digital twins are playing a pivotal role in advancing predictive maintenance capabilities.

How is predictive maintenance evolving with the introduction of autonomous vehicles?

Autonomous vehicles are generating vast amounts of data that can be leveraged for predictive maintenance, enabling more proactive and efficient fleet management strategies.

What impact does predictive maintenance have on the future of fleet management?

Predictive maintenance is revolutionizing fleet management by optimizing maintenance schedules, enhancing vehicle performance, and reducing operational costs in the long term.