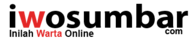

Delve into the world of fleet maintenance and its profound impact on company ROI. Learn how strategic maintenance practices can optimize operational efficiency and financial returns, setting the stage for a compelling exploration ahead.

Explore the intricacies of fleet management and discover the key factors that influence company ROI.

Importance of Fleet Maintenance

Proper maintenance of a company's fleet is crucial for ensuring smooth operations, reducing downtime, and ultimately impacting the company's ROI.

Key Components of a Fleet Maintenance Program

- Regular Inspections: Scheduled inspections help identify potential issues before they escalate, ensuring vehicles are safe and efficient.

- Preventive Maintenance: Following a proactive maintenance schedule can prevent costly breakdowns and extend the lifespan of vehicles.

- Documentation and Record-Keeping: Keeping detailed records of maintenance activities helps track expenses, identify trends, and make informed decisions.

- Training and Education: Providing training for drivers and maintenance staff ensures proper handling of vehicles and equipment, leading to better maintenance practices.

Impact of Poor Maintenance on Fleet Operations and Costs

Poor maintenance practices can have detrimental effects on fleet operations and costs, including:

- Increased Downtime: Unplanned breakdowns can lead to significant downtime, impacting delivery schedules and customer satisfaction.

- Rising Repair Costs: Neglecting maintenance can result in costly repairs due to major breakdowns that could have been prevented.

- Reduced Fuel Efficiency: Poorly maintained vehicles consume more fuel, increasing operational costs and reducing overall profitability.

- Safety Risks: Neglected maintenance can compromise the safety of drivers, passengers, and other road users, leading to accidents and potential liabilities.

Cost Analysis

In order to fully understand the impact of fleet maintenance on company ROI, it is crucial to analyze the associated costs and how they can be managed efficiently.

Direct Costs of Fleet Maintenance

Direct costs of fleet maintenance include expenses such as labor costs for mechanics, replacement parts, and tools. These costs are directly related to the upkeep and repair of the vehicles in the fleet.

Preventive vs. Reactive Maintenance Costs

Preventive maintenance involves regularly scheduled inspections and maintenance tasks to prevent breakdowns and costly repairs. While this approach may involve upfront costs, it is often more cost-effective in the long run compared to reactive maintenance.Reactive maintenance, on the other hand, involves addressing issues only when they arise, leading to unexpected downtime and higher repair costs.

By not proactively maintaining vehicles, companies may end up spending more on emergency repairs and replacement parts.

Efficient Maintenance Practices for Cost Reduction

Implementing efficient maintenance practices such as regular inspections, timely repairs, and keeping detailed maintenance records can help reduce overall costs. By identifying and addressing issues early on, companies can avoid costly breakdowns, improve fuel efficiency, and extend the lifespan of their vehicles.By investing in preventive maintenance and adopting efficient maintenance practices, companies can effectively manage costs and maximize their ROI in the long term.

Downtime and Productivity

Vehicle downtime can significantly impact a company's productivity and bottom line. When fleet vehicles are out of commission for maintenance or repairs, it can lead to delays in deliveries, reduced customer satisfaction, and increased operational costs.

Impact of Fleet Maintenance on Downtime

Effective fleet maintenance practices can help minimize unplanned downtime by identifying and addressing issues before they escalate into major problems. Regular servicing, inspections, and prompt repairs can keep vehicles in optimal condition, reducing the likelihood of breakdowns that require lengthy repairs.

Relationship between Maintenance Practices and Productivity

There is a direct correlation between the quality of maintenance practices and fleet productivity. Well-maintained vehicles are more reliable, efficient, and safe to operate, leading to increased uptime and better performance

Strategies to Minimize Downtime

- Implement a proactive maintenance schedule based on manufacturer recommendations and industry best practices.

- Conduct regular inspections to identify potential issues early on and address them promptly.

- Keep detailed maintenance records to track vehicle history and identify patterns of wear and tear.

- Provide ongoing training for drivers and maintenance staff to ensure they are knowledgeable about proper vehicle care and maintenance.

- Utilize telematics and fleet management software to monitor vehicle health and performance in real-time, allowing for proactive maintenance interventions.

Safety and Compliance

Maintaining fleet vehicles is crucial for ensuring the safety of drivers, passengers, and other road users. Regular maintenance helps identify and address potential safety issues before they escalate.

Role of Maintenance in Ensuring Compliance

Proper maintenance of fleet vehicles is essential for ensuring compliance with regulations set by governing bodies. This includes adhering to safety standards, emission requirements, and other legal obligations.

Consequences of Neglecting Maintenance

- Neglecting maintenance can lead to increased risk of accidents due to faulty equipment or mechanical failures.

- Failure to comply with regulations can result in hefty fines, penalties, and even legal action against the company.

- Poorly maintained vehicles are more likely to break down unexpectedly, causing disruptions to operations and delays in delivery schedules.

Asset Lifespan

Regular maintenance practices play a crucial role in extending the lifespan of fleet assets. By implementing a proactive maintenance schedule, companies can ensure that their vehicles and equipment remain in optimal working condition for a longer period of time.

Examples of Extended Asset Longevity

- Regular oil changes and fluid checks can prevent engine wear and tear, leading to a longer lifespan for the vehicle.

- Routine inspections and repairs of brakes and tires can enhance safety and prevent premature breakdowns, increasing the overall longevity of the fleet.

- Periodic cleaning and maintenance of equipment can prevent corrosion and damage, preserving the asset's lifespan.

Financial Implications of Prolonging Asset Lifespan

By prolonging the lifespan of fleet assets through regular maintenance, companies can significantly reduce their overall operational costs. Instead of incurring expenses on frequent repairs or premature replacements, investing in maintenance can lead to long-term savings. Additionally, extended asset longevity can improve resale value and overall return on investment for the company.

Outcome Summary

In conclusion, the discussion on How Fleet Maintenance Impacts Company ROI sheds light on the critical role of maintenance in enhancing profitability and sustainability. By prioritizing effective maintenance strategies, companies can unlock untapped potential and drive long-term success in their operations.

User Queries

How does fleet maintenance affect company ROI?

Effective fleet maintenance directly impacts company ROI by reducing operational costs, minimizing downtime, and extending the lifespan of fleet assets, ultimately leading to improved profitability.

What are the consequences of neglecting fleet maintenance?

Neglecting fleet maintenance can result in increased operational costs, higher downtime, safety risks, compliance issues, and shortened asset lifespan, all of which negatively impact company ROI.

How can companies optimize their ROI through strategic maintenance practices?

Companies can optimize their ROI by implementing preventive maintenance schedules, investing in efficient maintenance technologies, prioritizing safety and compliance standards, and regularly monitoring fleet performance to identify areas for improvement.